What kind of prototype are suitable for CNC prototype processing method?

Exterior prototypes

Exterior prototypes

prototype with material capability requirement(such as PP material, cannot fracture when bending)

prototype with material capability requirement(such as PP material, cannot fracture when bending)

prototype with metallic material

prototype with metallic material

prototype with big size(such as air-conditioning,color-TV)

prototype with big size(such as air-conditioning,color-TV)

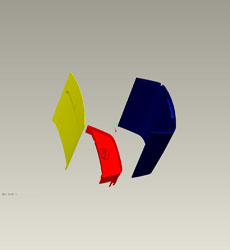

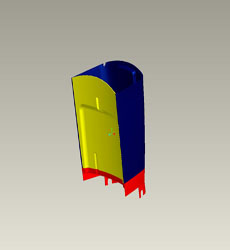

CNC prototype technological process:

What information you need to provide to us when adopt prototype cnc machining

processing method to make prototype?

Provide us 3D picture which the suffix is prt,step,iges,x_t, sldprt.

Provide us 3D picture which the suffix is prt,step,iges,x_t, sldprt.

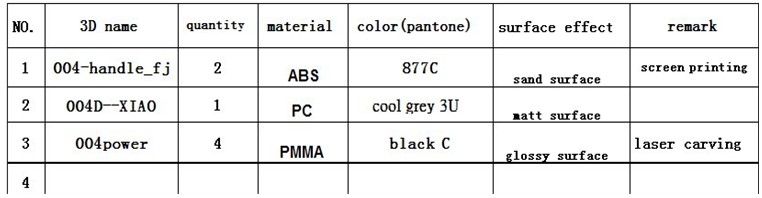

Explain the prototype’s quantity, material, color and surface effect of every 3D picture, you had better

Explain the prototype’s quantity, material, color and surface effect of every 3D picture, you had better

make a list. As show below:

Need to provide the internationally accepted color, such as pantone: cool grey 3c,but not only cold grey

Need to provide the internationally accepted color, such as pantone: cool grey 3c,but not only cold grey

There are three kinds surface paint effects: glossy surface, matt surface, sand surface ,every prototype

There are three kinds surface paint effects: glossy surface, matt surface, sand surface ,every prototype

need spray should explain the surface effect.

The prototype which the surface require screen printing and laser carving,need to provide the proportion

The prototype which the surface require screen printing and laser carving,need to provide the proportion

1:1 adobe illustrator(AI) or coreldraw file.And explain screen printing font pantone color.

Acrylonitrile Butadiene Styrene ( ABS )

Acrylonitrile Butadiene Styrene ( ABS )  Polyethylene ( PE )

Polyethylene ( PE ) Polyoxymethylene ( POM )

Polyoxymethylene ( POM )  Polypropylene ( PP )

Polypropylene ( PP ) polyamide ( PA )

polyamide ( PA )  Acrylic ( PMMA )

Acrylic ( PMMA ) Polycarbonate ( PC )

Polycarbonate ( PC )  polyvinyl chloride ( PVC )

polyvinyl chloride ( PVC ) phenolic

phenolic  Teflon

Teflon 6061 Aluminum

6061 Aluminum  standard steel ( 45# steel )

standard steel ( 45# steel ) 7075 Aluminum

7075 Aluminum  Stainless steel

Stainless steel Copper ( Cu )

Copper ( Cu )  mild steel

mild steel