What kind of prototypes are suitable for Vacuum casting processing method to make?

rubber prototype

rubber prototype

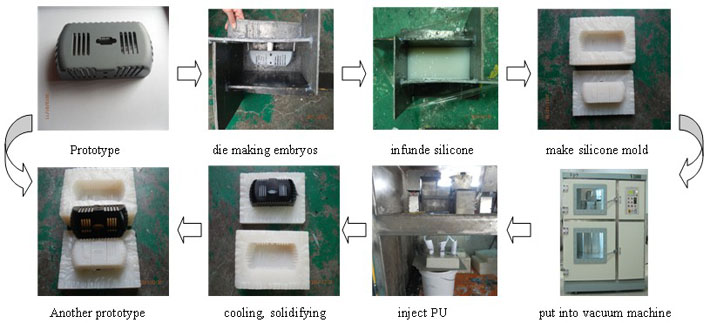

short run production of prototype

short run production of prototype

soft rubber prototype short run production prototype

Transparent PU- transparent prototype production

Transparent PU- transparent prototype production different hardness PU—produce all kinds of different hardness rubber prototype

different hardness PU—produce all kinds of different hardness rubber prototype Different performance PU-produce similar to the ABS ,PC,PP performance prototype

Different performance PU-produce similar to the ABS ,PC,PP performance prototype